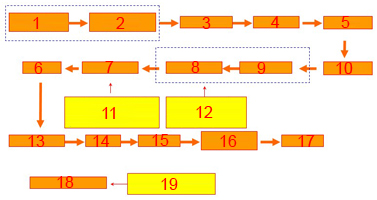

Flow Chart for the Production of Fruit and Vegetable Juices

1. Water Treatment Equipment

2. Plate Heat Exchanger

3. Mixed material

4. Melt material

5. Filter

6. Date Printing

7. Aseptic Filling

8. UHT Sterilization

9. Homogenization

10. Distribution

11. Strict inspection should be carried out prior to turning on the filling machine. One worker is required to stand beside the production line for monitoring.

12. At the UHT machine, there should be one worker standing on guard. The temperature range for the machine is 137±2℃

13. Applying U-Straw to the Package

14. Packing

15. Sending to the Warehouse

16. Inspecting the Product

17. Transport

18. CIP Cleaning System

19. It is used to clean all containers and drinking straws

| NO. | Configuration | Pictures |

| 1 | Water Treatment Equipment |  |

| 2 | Emulsion Tank |  |

| 3 | Mix Tank |  |

| 4 | Plate Heat Exchanger |  |

| 5 | Double-Filter |  |

| 6 | Pipeline Filter |  |

| 7 | CIP Cleaning System |  |

| 8 | Pipe Heat Exchanger |  |

| 9 | Working Platform |  |

| 10 | Valve |  |

| 11 | Pipes and Pipe Support |  |

| 12 | Sterilizer |  |

| 13 | Homogenizer |  |

| 14 | Degassing Tank |  |

| 15 | Pneumatic Diaphragm Pump |  |

| 16 | Pneumatic Diaphragm Pump |  |

| 17 | Electrical Cabinet and Electronic Control System |  |

| 18 | Steam Valve and Steam Traps |  |

| 19 | Beverage Pump |  |

| 20 | Installation and Commissioning | |

| 21 | BH3000 Aseptic Carton Filling Machine |  |

| 22 | Oil Burning Boiler |  |

| 23 | Air Compressor |  |

| 24 | Air Free-Dryer |  |

| 25 | Air Filter |  |

| 26 | Air Storage Tank |  |

| 27 | Shrink Film Packaging Machine |  |

Our company is an experienced juice production line manufacturer and supplier in China. We offer a vast array of products, including water treatment equipment, aseptic filling machine, U-straw applicator, and more.

Related Names

Fruit Juice Production Line | Vegetable Juice Production Plant | Juice Producing Unit | Fruit Juice Beltline